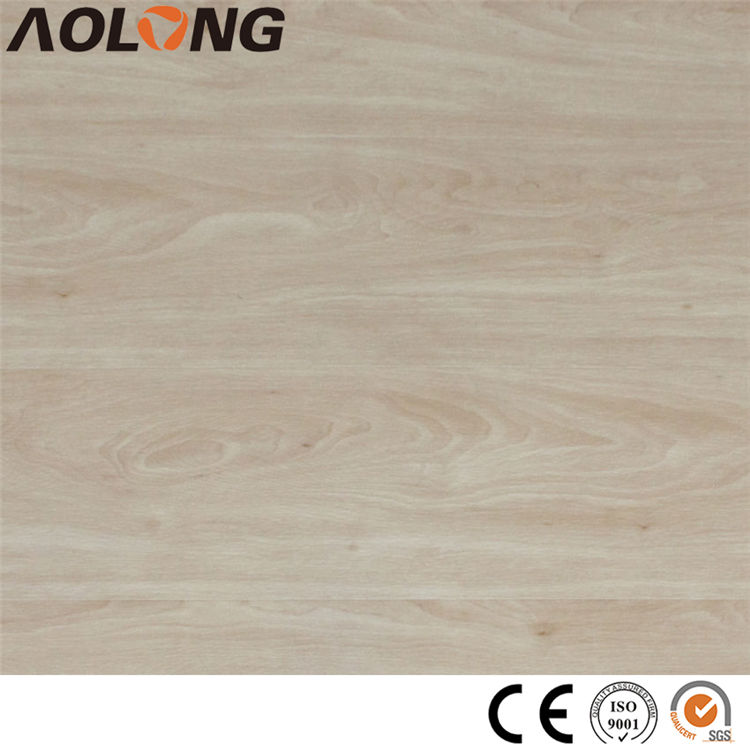

Fast delivery Ivory Floor Tiles - WPC Floor 1802 – Aolong Detail:

WPC-wood plastic composite, as its name implies, is a composite material of wood and plastic. Initially, the product was used for indoor and outdoor profiles, mainly for decoration. Later, it was applied to the interior floor. However, 99% of the core materials commonly used in the market for interior (WPC flooring) are PVC + calcium carbonate products (PVC foam products), so it can not be called WPC products. The physical properties of real WPC products are much better than ordinary PVC foam products, but the processing technology is difficult, so the market is generally PVC foam products.

WPC floor is composed of PVC wear-resistant layer, printing layer, semi-rigid PVC intermediate layer, WPC core layer and back sticking layer.

Discussion on WPC core

As the most important core part of WPC floor, its production is controlling the lifeline and future of this kind of floor. The biggest difficulty for manufacturers is the uniformity of density and the dimensional stability after heating. At present, the quality of the substrate can be found in the market is uneven, and the most common test we can usually do is to test the stability of the substrate by heating. The test requirements of international multinational enterprises are usually 80 ℃ and the test time is 4 hours. The measured project standards are: deformation ≤ 2mm, longitudinal shrinkage ≤ 2%, transverse shrinkage ≤ 0.3%. However, it is extremely difficult for WPC core production to achieve both standard products and cost control, so most enterprises can only improve the product density to achieve stability. The ideal core density is in the range of 0.85-0.92, but many enterprises increase the density to 1.0-1.1, resulting in high cost of finished products. Some enterprises produce non-conforming core regardless of product stability.

| Specification | |

| Surface Texture | Wood Texture |

| Overall Thickness | 12mm |

| Underlay(Optional) | EVA/IXPE(1.5mm/2mm) |

| Wear Layer | 0.2mm. (8 Mil.) |

| Size specification | 1200 * 150 * 12mm |

| Technical data of spc flooring | |

| Dimentional stability/ EN ISO 23992 | Passed |

| Abrasion resistance/ EN 660-2 | Passed |

| Slip resistance/ DIN 51130 | Passed |

| Heat resistance/ EN 425 | Passed |

| Static load/ EN ISO 24343 | Passed |

| Wheel caster resistance/ Pass EN 425 | Passed |

| Chemical resistance/ EN ISO 26987 | Passed |

| Smoke density/ EN ISO 9293/ EN ISO 11925 | Passed |

Product detail pictures:

Related Product Guide:

Our target is always to satisfy our customers by offering golden support, superior value and high quality for Fast delivery Ivory Floor Tiles - WPC Floor 1802 – Aolong, The product will supply to all over the world, such as: Finland, Portland, Greece, Our tenet is integrity first, quality . We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!